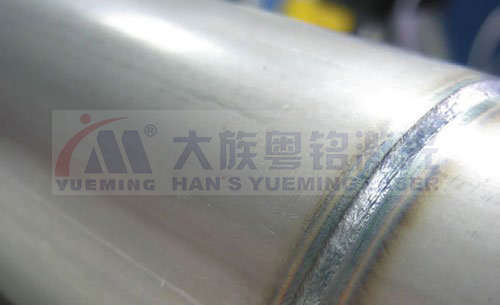

1. Heat conduction welding

When laser irradiates on the surface of the material, part of the laser is reflected and part of the material is absorbed; it changes the light energy into heat energy and then melts; the heat on material surface conducts and continues to transfer deeply, and finally two pieces are welded together.

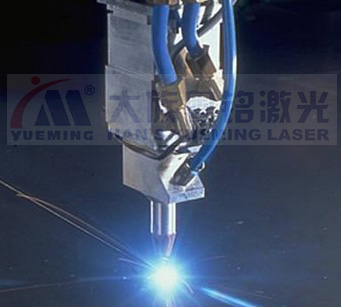

2. Deep laser welding

When laser beam with high power density irradiates on the surface of the material, the material absorbs light energy and converses into heat; material is melted even vaporized and produces large amounts of metal vapor. Under the counterforce when steam is out of the surface, the molten metal which is liquid pushes aside surrounding and forms pits and pits penetrate more deeply with continuous laser irradiation. After the laser irradiation, molten liquid around the pits reflux and cool, these two weld together.

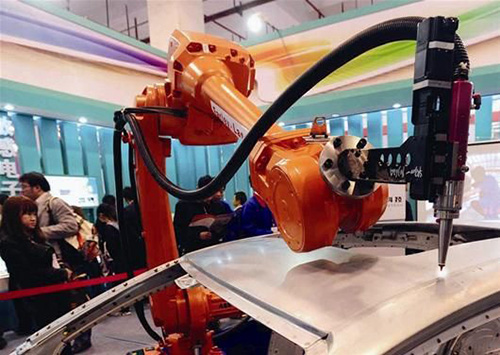

Continuous welding, which is relative to the welding point and short welding, is a welding joint connecting with another one and the middle is not broken. The welding mechanism is based on deep penetration of the keyhole effect; the depth to width ratio is large which can be up to 5: 1 above and welding speed is high and thermal deformation is small. It is widely used in high-power laser welding.

Laser welding machine is mainly used in machinery, automobile, ship and other industries. There are a few small power continuous lasers whose power is between dozens of tens and hundreds of watts. They are widely used in plastic welding and laser welding.

Super strength of laser welding machine

1, More fine welding

Minimum focusing spot diameter: 0.1 ~ 0.4mm; 0.2-25ms continuously adjustable pulse energy; pulse repetition frequency 0Hz = F = 2500Hz, especially suitable for precise welding for work pieces.

2, Low cost

The power loss of device just needs 500USD per year. Equipment almost has no supplies and almost doesn’t need daily maintenance, reducing the cost of debugging.

3, small space

The cooling way of laser welding machine is air cooling and it is compact, covering less than 1 square meters. It is easy to carry out line layout or automated integration.

Han's Yueming laser developed a variety of advanced new laser equipment for market choice like watches and jewelry marking machine, packing box date printer, laser drilling machine.

4. Every girl has wedding dress; see how beautiful your wedding dress is!

Girls with the most beautiful appearance wear the most beautiful wedding dress to marry the man she loves. It is a nice day when relatives and friends come to congratulate bride and bridegroom. It is the happiest moment in our whole life. It can be seen that every girl likes wedding and wedding dress is what girls love.

Wedding dress is finished step by step through embroidering with needles, cutting with scissors. Wedding dress is a beautiful noun; wedding dress is a romantic appointment.

With the development of the times, laser technology can also make wedding dress striking. Simple but precise carving makes wedding tail beautiful but not dull; bold, fast and accurate cutting makes the edge of wedding dress fashionable and generous. Whether it is red, white or pink, laser cutting machine can help girls to create a unique wedding dress-a set of exclusive own wedding dress.

Happy wedding dress is achieved with laser equipment; use your name and my name to make a romantic story. Therefore, every family name has a wedding dress and finally let’s see how beautiful your wedding dress is!

Han's yueming laser manufactures all kinds of industries laser equipment like fiber laser cutting machine, UV laser marker, laser engraving machine and so on.