According to the survey, shoe assembly line labor has been a traditional high-density assembly processing methods. In the industrial impact of flood, many of the traditional shoe line started to change the mode of operation, enterprises have transformation. Rising wages, and fewer and fewer worker get experience, so more and more labor-intensive processing methods become not popular.

As a new technology, the emergence of laser technology shows an innovative ways in this stage of shoe processing. Particular the laser robot, it attracts the attention in various production areas, footwear, lighting, packaging, sheet metal and other industries, and it is creasingly being used. Based on this, investigating laser cutting machine, laser engraving machine for the development of the shoe will be very necessary. It will show how laser technology affect and change the shoe assembly lines by analysis

‖ Industry Status:

In the development of the footwear industry, the various styles of shoes always appear. In this case, shoe industry, with a single style and long-term processing , harder to improve the market competitiveness, traditional shoe fashion took a hit. What followed was Han's Yueming automatic feeding laser cutting machine, leather laser engraving machine, automated processing to become the preferred choice for footwear industry.

‖ Solutions and advantages:

Automatic feeding laser cutting machine can automatically feed directly and gets wisdom of a material, it can be operated by a person, saving a lot of labor. The machine is easy to operate, without mold, owning high processing speed, especially for contour cutting punching advantage.

‖Products recommend:

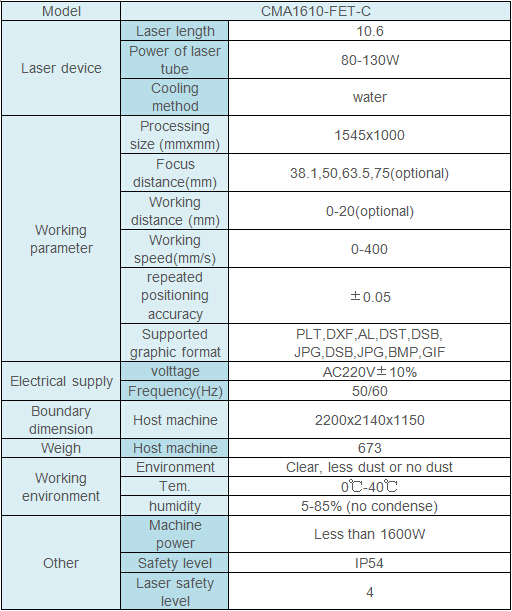

CMA1610-FET-C automatic feeding laser cutting machine

Machine performance:

‖ Features:

1. Arbitrary curve can cut quickly consecutively, the movement of cutting head likes the racing bicycle runs a perfect arc.

2. Full support CAD, CORELDRAW, GERBER, Tajima and other design software, the interface is friendly, meet the industry scene needs.

3. Multi-document function: CM Series devices can store up to 128 job file, in the case of completely not connect with the computer, the user can select a file on the laser engraver, easy mass production of 128 different kinds of products.

4. All-optical coupling isolation system is combined with high-speed differential input-output circuit design, while long-distance transmission signal is not distorted, getting high anti-jamming capability, the system supports 12-way work state output and 16 status input, the production site is easily interfaced with the user.

5. Mount shaped knives network with aviation aluminum, mold drawing, light weight, structural stability, no distortion, no fracture, no deviation, good flatness.

6. The belt can replace one by one, ready to clean, easy maintenance, service and maintenance, long life, high stability, low cost, support long time continuous operation fatigue.