ym@ymlaser.com

0086-18826950666

- Home

- About Us

- Products

- Application

- Service

- News

- Contact Us

By : Han's Yueming Laser Group 2020-11-19 Share: Back to list

If you are a wine lover

There must be a few bottles of wine in the house

The storage of wine is also an important part of wine culture

At first the wine rack was invented for better storing wine

With the continuous improvement of the quality of life

Various design of wine racks also emerge in endlessly

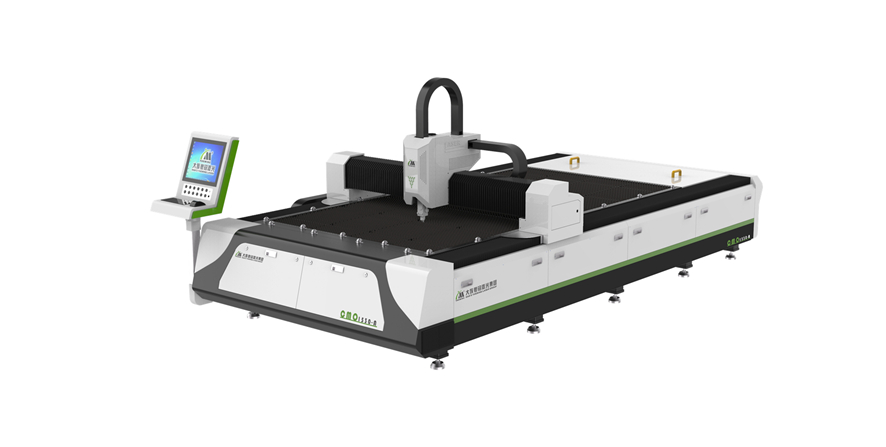

Creative wine rack was cut by high-speed fiber laser cutting machine

Which gives wine an artistic "safe place"

Good design of wine rack can make life more stylish

Laser processing without mold opening

No need to make molds for different designs of wine rack

Regardless of simple or complex shapes, the drawing can be completed only by the computer

The sheet metal can be cut and shaped at one time by the high-speed fiber laser cutting machine

Material waste can be reduced by software in automatic layout nesting

Which realizes the rational use of sheet metal

The superb high-speed fiber laser cutting machine gives precision to each sheet

Which shows the laser ingenuity in the subtleties

The cut surface is smooth and burr-free, which saves time to edge grinding

Various styles of wine racks are formed after bending or welding

Create unlimited ideas in a limited area

High-speed fiber laser cutting machine creates every shape of wine rack

Which realizes the diversification and multi-function of wine racks

It can be wine storage or home decoration

Which gives people a more artistic experience of storage and display

Recommend

1. Features

◆ Gantry double rack & pinion, double servo motor drive system, MHMD with great torque, 1G acceleration to ensure higher production efficiency;

◆ Imported large gantry milling machine, tempering treatment and vibration aging to eliminate stress, its geometric accuracy is within 0.3 mm;

◆ Crossbeam are made through drawing and finishing process, light weight, high rigidity, high dynamic performance;

◆ Germany IPG laser generator has high wall-plug efficiency over 30%, greatly saving power and achieving the highest efficiency;

◆ Auto-focus laser cutting head, integrates with detailed cutting parameters, easy for operation;

◆ Cutting head has leapfrog function, parabolic motion between the cutting contours. Automatic frog jump during switching contours, high cutting efficiency;

◆ It has the detection functions, such as: automatic diagnosis, fault isolation, fault analysis and data display, fast troubleshooting, can effectively reduce maintenance costs;

◆ Professional nesting software, highly compatible with cutting system, automatic edge searching and sharp corner smoothing functions, can achieve high-speed piercing and fast array scanning cutting functions.

2. Applications

Metal materials such as carbon steel, stainless steel, aluminum alloy, titanium alloy, galvanize sheet, brass, red cooper etc.

NEXT: Laser cut wooden music box, show you the beauty of the solar system

As a well-known 700w fiber laser cutting machine manufacturer, Han’s Yueming Laser produces laser cu...

Meet New High level Fiber Cutting machine...High level fiber cutting machine is the same as other laser equipment which has already recognized a...

How Much Does a 200W Laser Cutting Machine Cost?...Laser cutting machines for the cutting of non-metal materials are generally equipped with C02 laser...