ym@ymlaser.com

0086-18826950666

- Home

- About Us

- Products

- Application

- Service

- News

- Contact Us

By : Han's Yueming Laser Group 2021-1-11 Share: Back to list

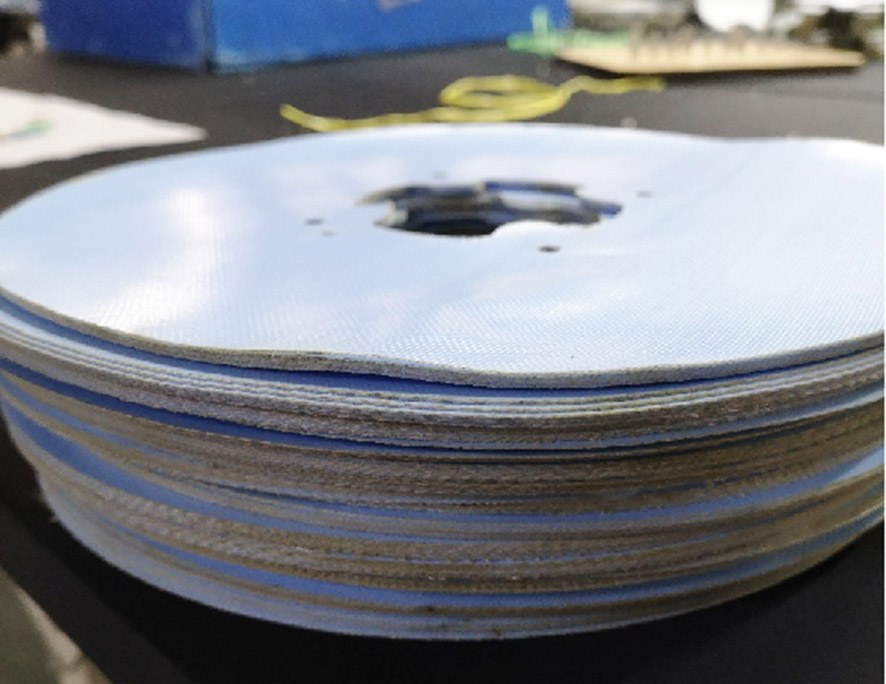

Car airbags can instantly inflate to form a soft air cushion when the car is in a collision to buffer energy and reduce the damage to the occupants. Practice has proved that the use of airbags can reduce injuries and deaths caused by car accidents, and is recognized as the protection that can reduce injuries caused by collisions in traffic accidents.

With the increasing number of cars on the road bringing more potential safety hazards, and the increasing importance of driving safety, the number of car airbags is also increasing. From the very beginning, only the front row was equipped, and now many models are equipped with airbags on the outside. Take the B-class car as an example, 6 airbags are standard, and some high-end models have 8 airbags.

In order to meet the increasing demand for airbag processing, the fourth-generation HCM3015C-DF-A automotive airbag double-head asynchronous laser cutting machine was launched by Yueming Laser Group in 2020. New design, experience, intelligence, safety, and new intelligence have realized the empowerment of a new generation of laser cutting equipment for automotive airbags, and that gives users an unprecedented superior experience, and that promotes rapid development of enterprises.

1. The function of double-head asynchronous laser cutting machine for automobile airbag

◆ The transmission structure is driven by linear motor, and the maximum acceleration can reach 2G, the maximum speed can reach 150m/min;

◆ It can realize double-head asynchronous cutting, intelligent and efficient distribution of cutting tasks, and maximize processing efficiency;

◆ Intelligently adjust the negative pressure value of exhaust air in the laser cutting area according to different working conditions;

◆ Fully enclosed design of cutting area, with intelligent fire protection monitoring system, effectively guaranteeing equipment safety;

◆ High-rigidity reinforced welded upper and lower bed, imported large gantry processing center precision milling, secondary annealing, effectively eliminating stress;

◆ Original imported Rofin Dc series laser generators, with good spot quality, stable output power, and high precision cutting;

◆ The beam is made of 7075 aviation grade aluminum. The domestic laser industry pioneered the welding process of this grade of aluminum, and its performance is extremely stable;

◆ Embedded multiple sensors for real-time monitoring and collection of various data; powerful OEE system meets the intelligent requirements of Industry 3.0 for equipment;

◆ The transmission system of the whole machine adopts CNC imported automatic lubrication system, which can cut continuously for 24 hours.

2. Applications

Automobile airbag double-head asynchronous laser cutting machine is mainly used for cutting automobile airbags such as automobile front airbags, automobile side airbags, automobile central airbags, and exterior airbags.

3. Equipment characteristics

All transmission mechanisms of the HCM3015C-DF-A auto airbag double-head asynchronous laser cutting machine adopts a fully automatic lubrication system, which can continuously perform 24-hour uninterrupted cutting work. It is the first in China that adopt an imported linear motor precision feeding system and an optimized design of the flying light path structure, which ensures that the feeding speed is stable and accurate, and at the same time, it can also ensure that the quality of the light spot on the entire cutting width is highly consistent.

In terms of production efficiency, the double-head asynchronous laser cutting module used by HCM3015C-DF-A is equipped with a high-speed and accurate traveling cutting system. According to various comprehensive data statistics, it depends on the shape and size of the cutting parts, and the efficiency of the cutting work of the whole machine can be increased by 15%-50%.

The reminder function of intelligent monitoring and active maintenance can be found in the auto airbag double-head asynchronous laser cutting machine. Through the real-time monitoring and collection of equipment operating data, the operating life of various key components can be accurately monitored, which is convenient for users to know when to change them. The parts are replaced or maintained in time, which effectively reduce the number of downtimes for replacement of spare parts and faulty maintenance.

At the same time, it provides end customers with a powerful MES system interface, supports remote monitoring and remote control of equipment, and it can receive and execute production planning instructions according to the company's order data, which greatly improves the intelligence and production efficiency of manufacturing enterprises.

Airbag is an important device for automobile safety protection. It can be used in conjunction with seat belts to provide effective collision protection for passengers. In a car collision, the airbag reduces the head injury rate by 25% and the facial injury rate by about 80%. In order to make the design of airbags more targeted, the processing should be more precise and easy, and shorten the delivery cycle is necessary. Nowadays, airbag manufacturers generally choose laser cutting equipment for processing.

The launch of HCM3015C-DF-A auto airbag double-head asynchronous laser cutting machine signifies that the technological leadership and monopoly maintained by similar European and American manufacturers for many years has broken by Yueming laser group, which makes the manufacturing technology of domestic auto airbag laser cutting equipment basically close to foreign countries. The technical level of the same quality and performance of similar laser equipment has brought more choices for domestic automobile airbag manufacturers. If you want to know about our dual-head asynchronous laser cutting machine for automobile airbags, please call the service hotline: 0769-8983 8888

As a well-known 700w fiber laser cutting machine manufacturer, Han’s Yueming Laser produces laser cu...

Meet New High level Fiber Cutting machine...High level fiber cutting machine is the same as other laser equipment which has already recognized a...

How Much Does a 200W Laser Cutting Machine Cost?...Laser cutting machines for the cutting of non-metal materials are generally equipped with C02 laser...