ym@ymlaser.com

0086-18826950666

- Home

- About Us

- Products

- Application

- Service

- News

- Contact Us

By : Han's Yueming Laser Group 2020-12-28 Share: Back to list

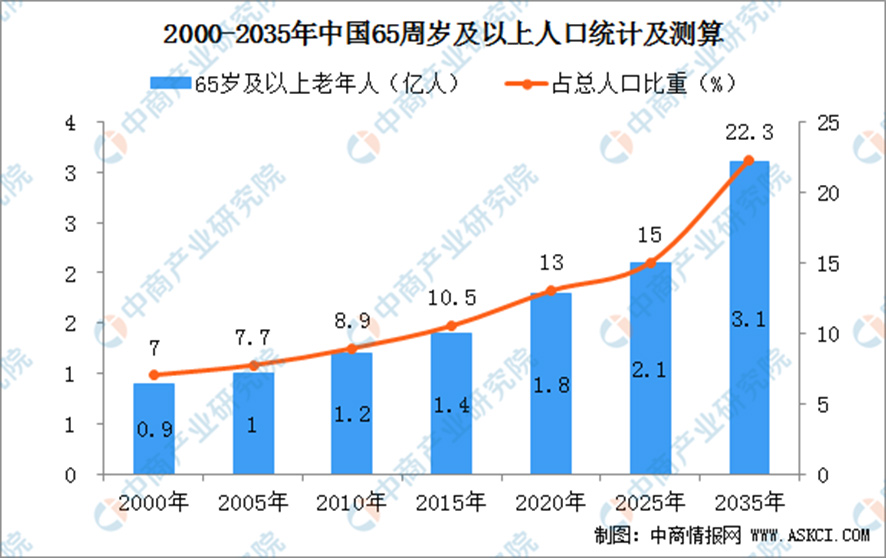

The aging era of China is coming. According to statistics, the proportion of people over 65 in China has risen to more than 13%. According to internationally recognized standards, 7%-14% of the population over 65 is slightly aging, 14% -20% is moderate aging, and 20%-40% is severe aging. In other words, China is already on the brink of moderate aging.

Once a person is getting old, then they walk or run slowly, especially the disabled elderly who lose the ability to take care of themselves, they only rely on family care. Have you encountered the following nursing troubles? Such as eat, stand up, go to the toilet, wash hair, infusion, and sit up. Traditional nursing care is exhausting as both the old and caregivers are suffering.

These troubles can be solved by a modern nursing bed. With the development of medical and health services, scientific and technological elderly care has become the norm, and patients have received better care. Like a medical care bed, it has evolved from a single lying function to a composite medical furniture integrating multiple functions, such as raising back and legs, turning over, infusion, eating, defecation, guardrails and moving, which satisfies different people, including the elderly, in the aspects of treatment, rehabilitation, and life. Literally, having a modern nursing bed which makes nursing more convenient, comfortable and safe for family.

In China, the nursing bed market is developing rapidly. On the one hand, the potential needs of disabled elderly and home patients are being tapped, especially for elderly care needs. On the other hand, the price is not that high, which makes most families afford. That depends on the rise of China's manufacturing industry, which has greatly reduced the manufacturing cost of the entire product. For example, pipe cutting, which accounts for a large proportion in the production of nursing beds. Therefore, it has been gradually introduced into the pipe processing flow of nursing beds in recent years, and it meets the design requirements of the high-end market of nursing beds and reducing costs.

The manufacture of nursing beds is not easy. Take metal pipes with a lot of materials as an example, there are amount of pipe parts with shape of long or short, round or square needed to be processed including bed body, back frame, turning frame, beam frame, protective fence, rocking handle, infusion stand and so on. At the same time, each pipe component will be designed with multiple openings of different sizes and positions to simplify the subsequent assembly of the pipe components of the nursing bed. Therefore, the functions of raising the back, raising the legs, turning over, and armrests can be achieved. The more functions and the more complex the design, the less conducive to production, which is undoubtedly a huge challenges of pipe processing.

In terms of the production investment and production quality of metal pipe parts in each part of the nursing bed, it consumes a lot of molds, manpower and high investment costs, compared with traditional pipe processing methods that require multiple processes such as cutting, punching, and drilling. However, the tube processing needs of the nursing bed can be met by the fully automatic fiber laser tube cutting machine. Since that allows the nursing bed to have higher production efficiency, better product quality and lower processing costs.

Advantages of fully automatic fiber laser tube cutting machine

1. Low investment cost: mold-less production, avoiding the expensive cost of manufacturing, replacing, maintaining and storing molds;

2. Short preparation cycle: the traditional stamping and blanking mold manufacturing, trial, and optimization links are omitted, and the production preparation cycle that takes only one day or even a few hours can be completed;

3. Highly flexible production: It can process different metal pipes such as stainless steel pipes, aluminum pipes, copper pipes, and there is no restriction on the product outline. Square pipes, round pipes, special-shaped pipes can be cut;

4. High-speed and intelligent: automatic loading and unloading, automatic calibration and detection, automatic setting of the optimal processing path, automatic cutting after programming, and general workers can be employed after training, which saves labor costs;

5. Realization of complex design: there is non-contact laser cutting has no restrictions of non-contact laser cutting, and it makes the processing of any graphics easier, and meets the design needs of mid-to-high-end nursing beds;

6. High cutting quality: capacitive fiber laser cutting head, high-precision servo motor drive, and high-precision transmission mechanism achieve high accuracy in size, position and trajectory. The non-contact cutting process ensures that the pipe does not produce surface crack to obtain better edge quality than punching blanking. It can be directly used for welding without secondary grinding.

Satisfying the needs of nursing staff and patients for equality, care, efficiency, and humanization, enhancing medical social interaction, and extending the life cycle are all necessary for an excellent medical care bed.

As an excellent medical care bed processing equipment, the fully automatic fiber laser tube cutting machine brings the feeling of care and efficiency to the processing enterprise: a more user-friendly operation design greatly reduces manpower consumption and makes operators get rid of repetitive, heavy manual labor and dangerous operations; more efficient and energy-saving characteristics make the company's unit productivity higher and bring huge profits to the company; at the same time, laser cutting brings a new degree of processing freedom and also helps designers put forward their ideas, optimize the design, and make the nursing bed experience better.

Recommended -HyTube series fully automatic fiber laser tube cutting machine

Features of automatic fiber laser tube cutting machine:

◆ CCD pipe section recognition system;

◆ Automatic bundle feeding system;

◆ Automatic sorting system for finished pipe fittings;

◆ Floating trusteeship for pipes;

◆ Intelligent remote monitoring system;

◆ Automatic measurement system for tube sheet length.

Materials:

Carbon steel tube cutting, aluminum alloy tube cutting, stainless steel tube cutting, titanium alloy tube cutting.

NEXT: Hair dryer laser marking machine is the combination of technology and aesthetics of winter products

As a well-known 700w fiber laser cutting machine manufacturer, Han’s Yueming Laser produces laser cu...

Meet New High level Fiber Cutting machine...High level fiber cutting machine is the same as other laser equipment which has already recognized a...

How Much Does a 200W Laser Cutting Machine Cost?...Laser cutting machines for the cutting of non-metal materials are generally equipped with C02 laser...