ym@ymlaser.com

0086-18826950666

- Home

- About Us

- Products

- Application

- Service

- News

- Contact Us

By : Han's Yueming Laser Group Share: Back to list

Dongguan is famous for the technical capabilities of the manufacturing industry, which is called the world’s factory. Dongguan laser welding machines are widely used in Dongguan manufacturing enterprises. Fiber laser welding machine has handheld and three-dimensional robot type. The main introduction here is more about handheld laser welding machines.

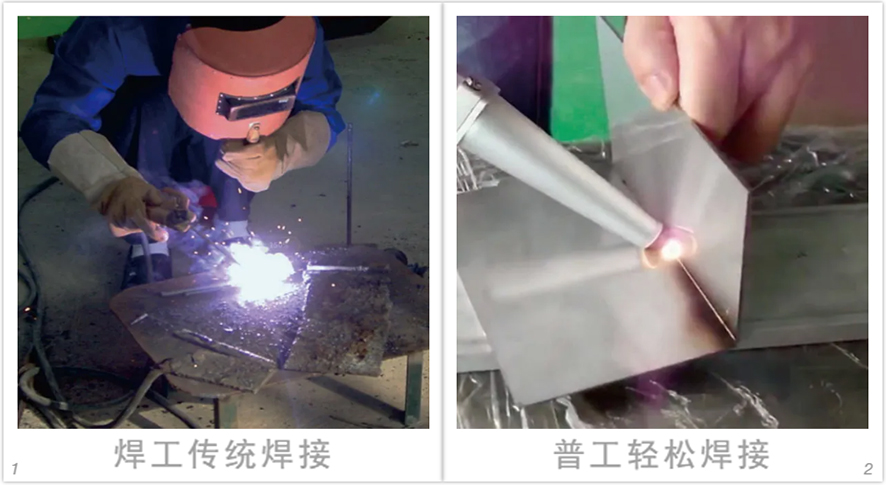

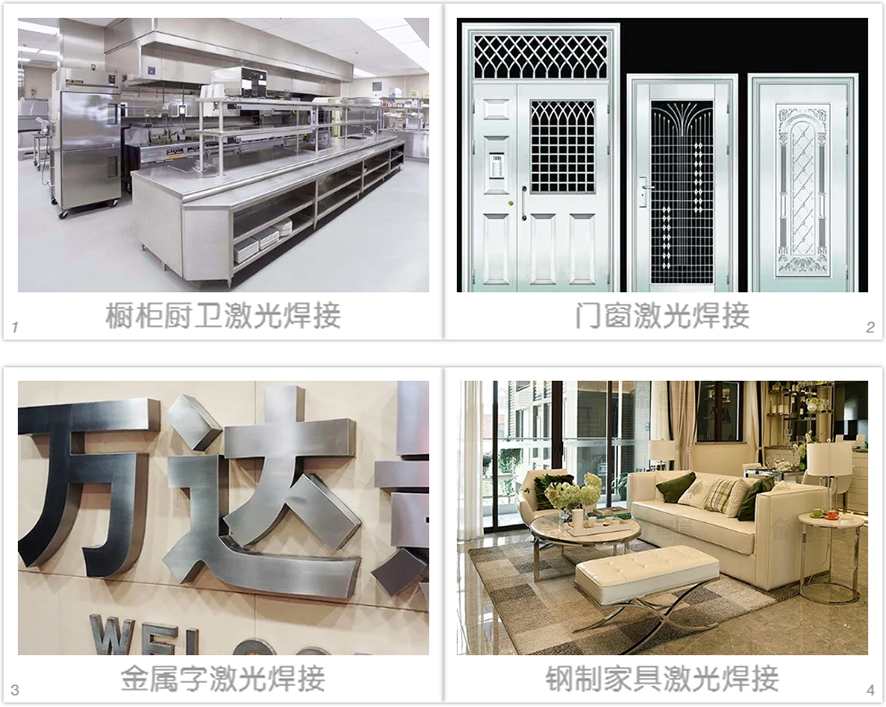

Traditional welding methods such as argon arc welding are mainly used in the fields of sheet metal, water tanks, distribution boxes, cabinets, kitchens, bathrooms, stainless steel door and window guardrails. Nowadays, in these welding application scenarios, the traditional welding method which is not safe and environmentally friendly and also not efficient, convenient and beautiful enough, is gradually be replaced by handheld laser welding machines.

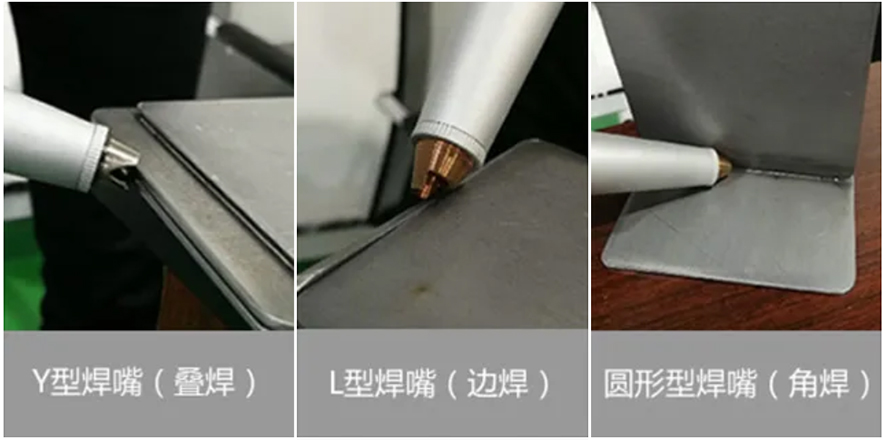

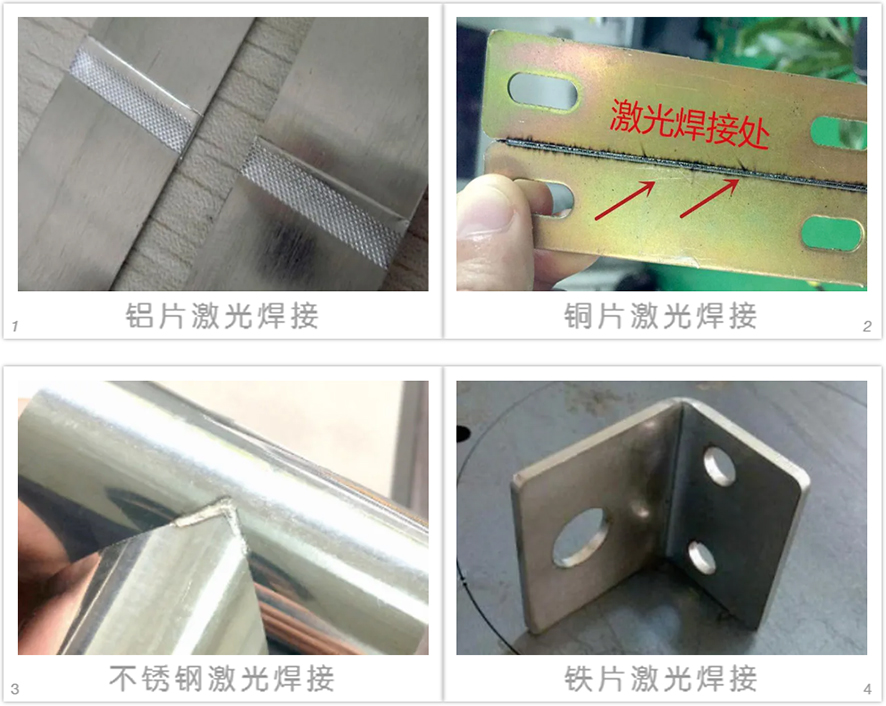

The handheld laser welding machine can be used for welding aluminum, iron, stainless steel, copper and other metal sheets of the same materials, and the mixed welding of aluminum copper, stainless steel copper and other materials. Dongguan laser welding machine general workers can be trained to work without professional welder certificates.

Dongguan laser welding machine is more energy-saving and environmentally friendly and power consumption which is less than 1.5 degrees per hour. At the same time, there is no need to add welding wire during the welding process, and the welding is stronger. In terms of welding efficiency, the laser welding speed is faster, the penetration is deeper, and the welding yield of different materials is high, which is 2-10 times faster than the traditional welding speed.

Dongguan laser welding machine has also taken full advantage of cost considerations. Taking argon arc welding as an example, argon arc welding requires mature welders, while hand-held laser welding only requires ordinary operators. The annual labor cost of a mature welder is higher than that of ordinary operators. Also, the efficiency of handheld laser welding is higher than that of argon arc welding. Besides, argon arc welding generally requires polishing after welding, while hand-held laser welding almost does not require polishing, or only need slightly polishing, which saves part of the labor cost of the polishing worker.

Unexpectedly, welding machines can be welded without wire bonding. The combination of fiber laser and welding process has produced a wonderful chemical reaction, which subverts the traditional welding method! What do you think of the Dongguan laser welding machines?

PREVIOUS: What is the welding effect of laser welding machine on bathroom hardware?

NEXT: Hermès in the chopsticks world: laser-engraved stainless steel chopsticks, have you used it?

As a well-known 700w fiber laser cutting machine manufacturer, Han’s Yueming Laser produces laser cu...

Meet New High level Fiber Cutting machine...High level fiber cutting machine is the same as other laser equipment which has already recognized a...

How Much Does a 200W Laser Cutting Machine Cost?...Laser cutting machines for the cutting of non-metal materials are generally equipped with C02 laser...