ym@ymlaser.com

0086-18826950666

- Home

- About Us

- Products

- Application

- Service

- News

- Contact Us

By : Han's Yueming Laser Group Share: Back to list

As Chinese consumers' preference for coffee continues to increase, and this brings development opportunities to the sheet metal fiber laser cutting machine cutting coffee machine market.

A perfect coffee machine

Need a humanized design concept

Need more exquisite craftsmanship

It must meet both practical requirements and aesthetic principles

Sheet metal fiber laser cutting machine can meet the needs of both

Use high-precision sheet metal fiber laser cutting machine to cut the metal panel of the coffee machine

The cutting machine can easily handle metal sheets of various thicknesses, shapes and sizes

Cutting, hollowing, punching; round, rectangular, special-shaped...

The laser cutting machine can meet the various needs of coffee machine parts processing

The sheet metal fiber laser cutting machine can automatically typeset nesting materials through the computer, reduce material waste, and realize the rational use of metal plates. The cutting edges are smooth and clean, and the aesthetics of the coffee machine is also improved by a level.It is pleasing to use the coffee machine in the office or at home

With the help of sheet metal fiber laser cutting machine, the category of coffee machines has become more diversified and multifunctional, bringing people a different coffee consumption experience.

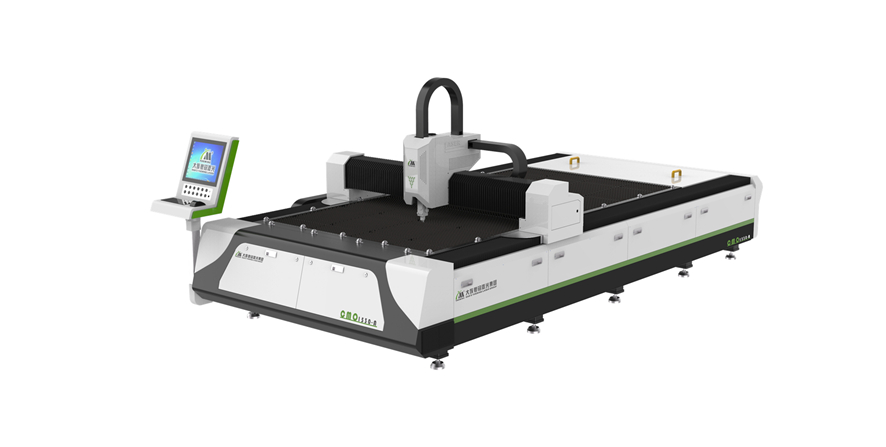

Recommended equipment:

sheet metal fiber laser cutting machine

1.Features

u Gantry double rack & pinion, double servo motor drive system, MHMD with great torque, 1G acceleration to ensure higher production efficiency;

u Imported large gantry milling machine, tempering treatment and vibration aging to eliminate stress, its geometric accuracy is within 0.03mm;

u Crossbeam are made through drawing and finishing process, light weight, high rigidity, high dynamic performance;

u Germany IPG laser generator has high wall-plug efficiency over 30%, greatly saving power and achieving the highest efficiency;

u Auto-focus laser cutting head, integrates with detailed cutting parameters, easy for operation;

u Cutting head has the leapfrog function, parabolic motion between the cutting contours. Automatic frog jump during switching contours, high cutting efficiency;

u It has the detection functions, such as: automatic diagnosis, fault isolation, fault analysis and data display, fast troubleshooting , can effectively reduce maintenance costs;

u Professional nesting software, highly compatible with cutting system, automatic edge searching and sharp corner smoothing functions, can achieve high-speed piercing and fast array scanning cutting functions.

2. Process application

Sheet metal fiber laser cutting machine is mainly used for rapid cutting of carbon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, aluminum-plated zinc sheet, brass, copper and other metal materials.

As a well-known 700w fiber laser cutting machine manufacturer, Han’s Yueming Laser produces laser cu...

Meet New High level Fiber Cutting machine...High level fiber cutting machine is the same as other laser equipment which has already recognized a...

How Much Does a 200W Laser Cutting Machine Cost?...Laser cutting machines for the cutting of non-metal materials are generally equipped with C02 laser...