ym@ymlaser.com

0086-18826950666

- Home

- About Us

- Products

- Application

- Service

- News

- Contact Us

By : Han's Yueming Laser Group Share: Back to list

Today is 9.29 World Walking Day. The World Health Organization and some research institutes have pointed out that walking is one of the best sports in the world. It is not restricted by age, time and venue. It is simple and easy to do and keep fit. Equipping a good pair of shoes is an important condition for walking. The birth of a pair of shoes generally requires about a dozen major links such as cutting, sewing, sole forming, and clip forming. Among them, the sole glue spraying machine "shoe sole glue" is an indispensable process for all shoe types. The sole needs to go through the production process of coating treatment agent and glue application. The quality of glue application is related to the quality of finished shoes.

Many shoe manufacturers use semi-automatic equipment to complete the gluing of shoe soles manually. However, the efficiency of manual gluing is not high and unstable, and the thickness of the glue is uneven. It is easy to cause problems such as glue overflow and lack of glue, and it is difficult to meet the quality requirements. In addition, toxic and hazardous substances in the production environment will affect the health and safety of employees, and the sole glue spraying process is in urgent need of automation upgrades. The automatic sole glue spraying machine came into being, and through the intelligent, automated, and refined production mode, it helps shoe manufacturers complete the transformation and upgrading of sole glue spraying technology.

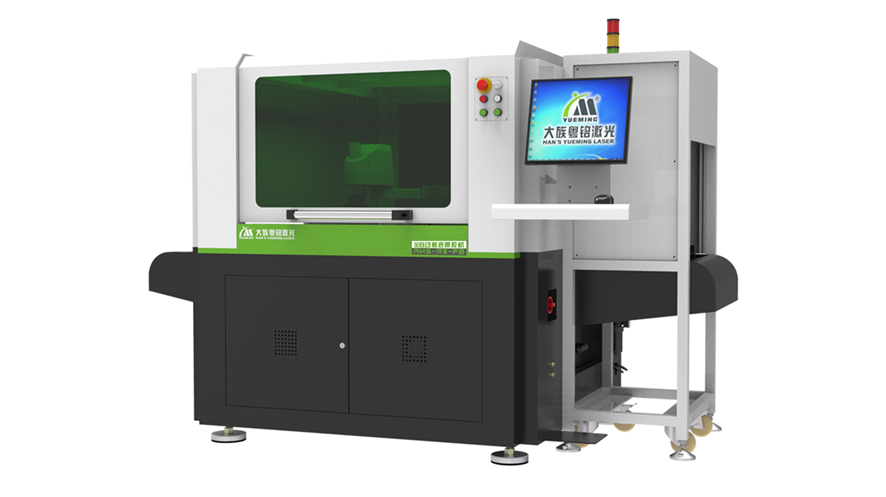

Automatic sole glue spraying machine AMS-R5-FB

1 Process application

The automatic sole glue spraying machine has a wide range of applications. Whether it is sports shoes, canvas shoes, or sneakers, tooling shoes, leather shoes and other different footwear, the all-round automatic glue spraying machine is completely applicable. The use of a fully automatic sole spraying machine for sole spraying has become a more intelligent processing method in the sole spraying process.

2 Features

◆The imported high-precision 3D laser scanning system can accurately and quickly scan the three-dimensional size of the sole;

◆Independently researched and developed sole glue software and special controller, which can automatically generate glue spray path according to sole size and glue parameters, and spray glue path without programming without manual intervention;

◆The software is easy to operate, different sizes or similar soles can use the same set of parameters for intelligent matching;

◆Two 5-axis robots work together, and the production efficiency can reach 240 pairs/hour;

◆With UV detection and glue activation and curing function to ensure the quality of glue spray;

◆It has humanized design such as easy to learn and easy to use, easy to learn and use, the nozzle is not easy to be blocked, and the glue accumulation of the conveying mechanism is easy to clean;

◆According to production requirements, support the customization of loading and unloading interface automation functions, production management function customization, and MES system interface development customization.

3 process advantages

01Strong applicability

It is suitable for different specifications, different models and different sizes of soles. It can spray glue on the soles of different colors and materials.

02 fast

Automatic sole glue spraying machine Two 5-axis robots work together, and the sole scanning and glue spraying can be completed in 6-8 seconds.

03Less loss

The glue trajectory of the automatic sole glue spraying machine is controlled by the program to be more stable, with less glue consumption, uniform glue spraying, and avoiding glue waste.

04Safety and environmental protection

Robotic operation effectively isolates the volatilization of the adhesive. Workers have no direct contact with the glue, reducing the threat to the operator's health from the volatilized glue and reducing the risk of occupational diseases.

05Intelligent System

The self-developed sole sole software automatically calculates the glue spray path, automatically adjusts the nozzle posture, no programming is required, and it is more humane and intelligent in dealing with local overflow and lack of glue, and the rework rate is greatly reduced.

06 Extremely Simple

The spraying parameters of the sole spraying machine are easy to learn and use, and the operation is convenient. Workers can get on the job after simple training, which can get rid of the problem of excessive dependence on the experience of the traditional spraying process.

PREVIOUS: What are the advantages of laser cleaning machine for rust removal

As a well-known 700w fiber laser cutting machine manufacturer, Han’s Yueming Laser produces laser cu...

Meet New High level Fiber Cutting machine...High level fiber cutting machine is the same as other laser equipment which has already recognized a...

How Much Does a 200W Laser Cutting Machine Cost?...Laser cutting machines for the cutting of non-metal materials are generally equipped with C02 laser...