ym@ymlaser.com

0086-18826950666

- Home

- About Us

- Products

- Application

- Service

- News

- Contact Us

By : Han's Yueming Laser Group Share: Back to list

Fiber laser cutting machine has become the absolute flagship product in the metal cutting field, combined with intelligent technologies such as automatic edge finding, automatic typesetting, and leapfrogging functions, it has a broad development prospect. Nowadays, industries such as automobiles, electronics, machinery, aviation, and steel have basically completed the upgrading of traditional craftsmanship with laser processing technology, entering the era of "light manufacturing".

When the fiber laser cutting machine cuts large-format and medium-thick metal sheets in the sheet metal industry, in order to improve the utilization of the sheet and facilitate programming, the straight edge of the sheet must be parallel to the X-axis processing direction of the machine tool before laser cutting. Normally, manual calibration is used, which has low efficiency, large errors and serious material waste, which affects processing efficiency. We applied the automatic edge finding function in the fiber laser cutting machine. This function is easy to operate, high precision, and short time-consuming, which solves this problem well.

1. Introduction of automatic edge finding function

The large-format and medium-thick metal plates are placed on the closed machine tool workbench, and workers only need to press the "edge finding" button, and the equipment will calculate the inclination angle of the plate within a few seconds, and the coordinate system of the machine tool will respond accordingly. The rotation of the fiber laser cutting machine ensures that the X direction of the fiber laser cutting machine is parallel to the long and straight side of the plate.

⑴System composition

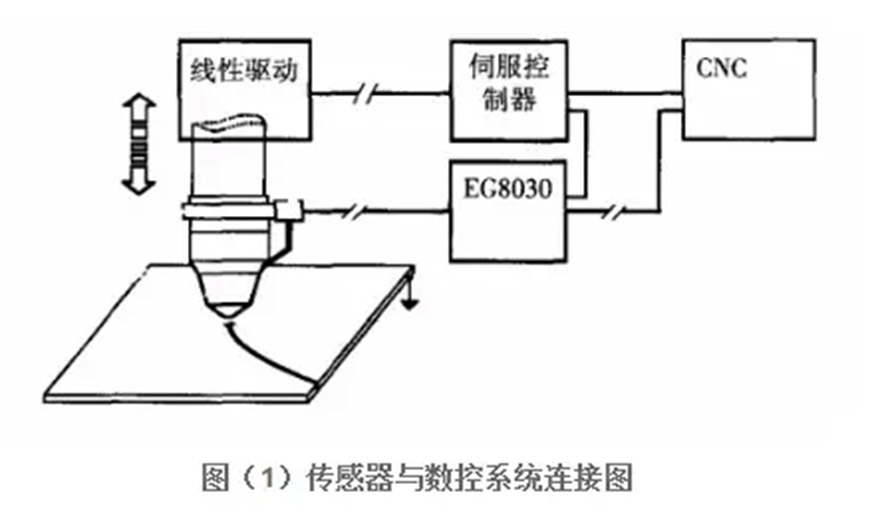

The hardware connection and composition required for the fiber laser cutting machine to realize the automatic edge finding function is shown in Figure (1), which mainly includes CNC, servo control, linear drive, sensors, etc.

⑵The principle of automatic edge finding function

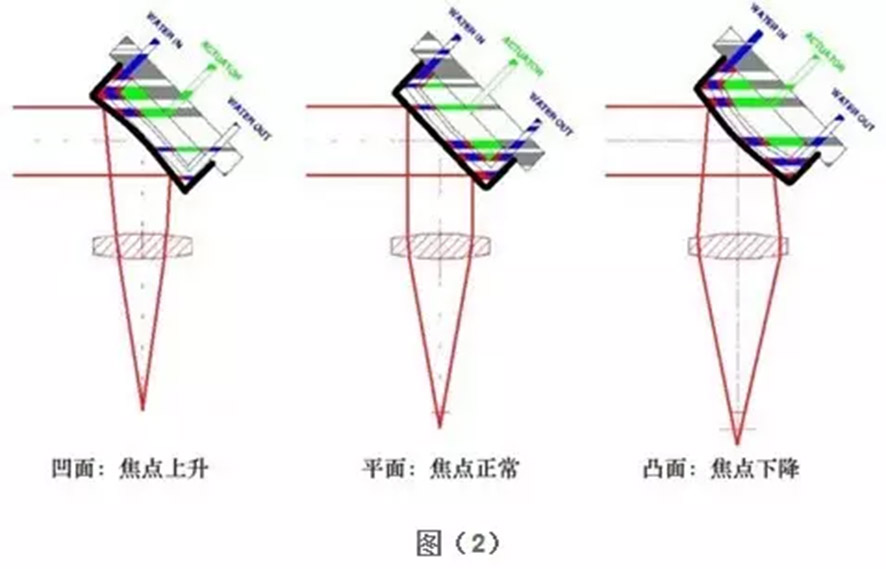

As shown in Figure 2 below, when the sheet is placed on the workbench, if it is skewed, it may cause waste during cutting. If the inclination angle and origin of the sheet can be sensed, the processing procedure of the fiber laser cutting machine can be adjusted to suit the angle and position of the sheet to avoid waste. The automatic edge finding function came into being.

The automatic edge finding function is applied to the fiber laser cutting machine, which solves the problem of low material utilization in the processing of large-format and medium-thick metal plates, saves the time for calibrating the plates, effectively improves production efficiency, and provides users with This brings objective benefits and at the same time increases the degree of automation of the processing and cutting machine.

Recommended equipment: open fiber laser cutting machine

Open fiber laser cutting machine

1. Features:

1. Adopt gantry double rack and pinion, double servo motor transmission structure, high inertia and large moment output, maximum acceleration can reach 1.0G, effectively improve customer's production efficiency;

2. Using imported large-scale gantry machine tool, using high-strength square tube welding technology, the geometric accuracy of the machine tool is within 0.03mm, which has high precision and stability;

3. The beam is made of drawn aluminum profile finishing process, with light weight, high rigidity and good dynamic performance;

4. The laser electro-optical conversion efficiency is high, reaching more than 30%, which can greatly save power consumption and achieve very high production efficiency;

5. Equipped with automatic focusing function, the perforation time is reduced by 80% compared with ordinary cutting heads, and the complete cutting process database makes the operation more intelligent and convenient;

6. Parabolic motion is used between the cutting contours of the cutting head, and the contour switching process automatically realizes "leapfrogging", which greatly improves the cutting efficiency;

7. With function testing, automatic diagnosis, fault isolation, fault analysis and data display system, fast troubleshooting can effectively reduce the cost of after-sales service;

8. Professional programming nesting software, highly compatible with cutting system, with graphics nesting, automatic edge seeking and sharp corner smoothing processing functions, can achieve high-speed blasting perforation and fast array scanning cutting functions.

2. Process application

The open fiber laser cutting machine is mainly used for cutting carbon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, galvanized sheet, brass, copper and other metal materials quickly.

PREVIOUS: Necessary stationery at the beginning of school: memo paper engraved by laser engraving machine.

NEXT: Do you really know everything about handheld laser welding machine equipment?

As a well-known 700w fiber laser cutting machine manufacturer, Han’s Yueming Laser produces laser cu...

Meet New High level Fiber Cutting machine...High level fiber cutting machine is the same as other laser equipment which has already recognized a...

How Much Does a 200W Laser Cutting Machine Cost?...Laser cutting machines for the cutting of non-metal materials are generally equipped with C02 laser...