ym@ymlaser.com

0086-18826950666

- Home

- About Us

- Products

- Application

- Service

- News

- Contact Us

By : Han's Yueming Laser Group 2021-1-6 Share: Back to list

The function of the distribution box is to cut off and connect the power, which effectively control each power line to achieve the purpose of power use safely. Both households and buildings, a distribution box is needed to be controlled and protected. Laser cutting stainless steel distribution box, which is non-standard customization but extremely effective.

The distribution box is made of stainless steel

The advantages of stainless steel are anti-corrosion, anti-rust, strong and durable

So, it can be used in any kind of environment and weather

In the processing of stainless steel distribution boxes, the following processing is involved

Shell panel cutting, rainproof canopy cutting, galvanized bottom plate cutting

Hollow out of heat dissipation hole, wall hole and outlet hole

Stainless steel laser cutting machine is particularly suitable for cutting and hollowing out sheet metal

As laser cutting is with fast cutting speed, good quality, no cutting force and no deformation in processing

Which can quickly and accurately complete the processing work of the distribution box

And it vividly shows the beauty of metal lines

Distribution boxes are generally non-standard products and needed to be customized

Compared with conventional processing methods

The stainless steel laser cutting machine is with excellent adaptability and flexibility

So greater space for the design and manufacture of distribution boxes can be provided by the fiber laser cutting machines

Also, specific design drawings can be customized

No matter how complex the graphics are, they can be cut without increasing the cost

Laser cutting is "tailor-made" for users

As small batch, multiple varieties, low cost and fast processing can be achieved by fiber laser cutting machines

Advantages of laser processing sheet metal:

1. Mold opening and molds for different designs are not required, which saves a lot of production costs;

2. It is with high flexibility and unlimited graphics. Regardless of simple or complex shapes, it can be cut and formed by laser at one time. It can also realize automatic cutting and nesting, which improves material utilization;

3. It is with fast cutting speed, high precision, flat and smooth cutting edges and no burrs, which reduces the defect rate of products and shortens the product production cycle;

4. Fiber laser cutting machine does not produce chemical substances that are harmful to the human body and the environment, and it meets the national environmental protection requirements. Also, it reduces environmental pollution and it helps manufacturers of distribution boxes to optimize the working environment.

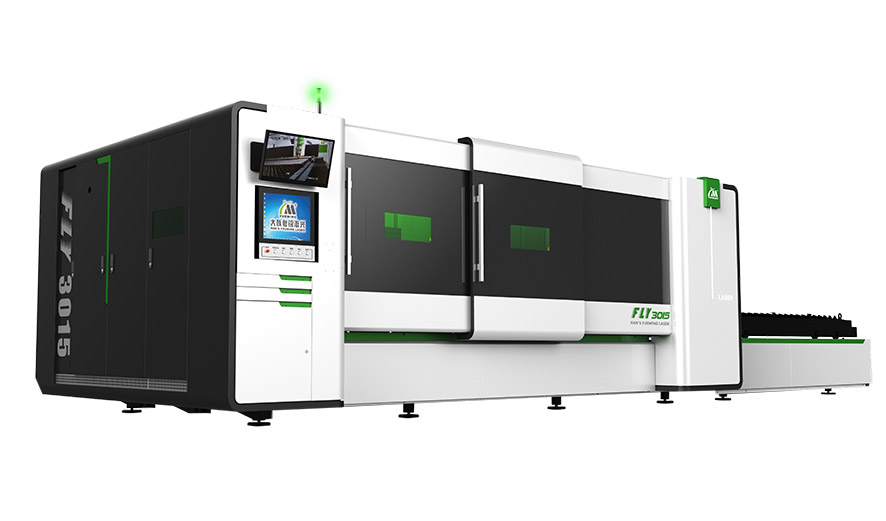

Recommendation-FLY fiber laser cutting machine

1. The functional characteristics of FLY fiber laser cutting machine

1. The functional characteristics of FLY fiber laser cutting machine

◆ Safe and reliable external protection device;

◆ Convenient operation, simple and intelligent;

◆ Self-translating double-layer exchange table;

◆ Intelligent remote diagnosis function;

◆ Visual remote monitoring function [optional]

2. Application

FLY fiber laser cutting machine is mainly used for laser cutting and hollowing processing of various metal materials such as stainless steel, aluminum alloy, carbon steel, titanium alloy, galvanized sheet, aluminum-plated zinc sheet, brass, and copper.

As a well-known 700w fiber laser cutting machine manufacturer, Han’s Yueming Laser produces laser cu...

Meet New High level Fiber Cutting machine...High level fiber cutting machine is the same as other laser equipment which has already recognized a...

How Much Does a 200W Laser Cutting Machine Cost?...Laser cutting machines for the cutting of non-metal materials are generally equipped with C02 laser...