ym@ymlaser.com

0086-18826950666

- Home

- About Us

- Products

- Application

- Service

- News

- Contact Us

By : Han's Yueming Laser Group 2020-11-24 Share: Back to list

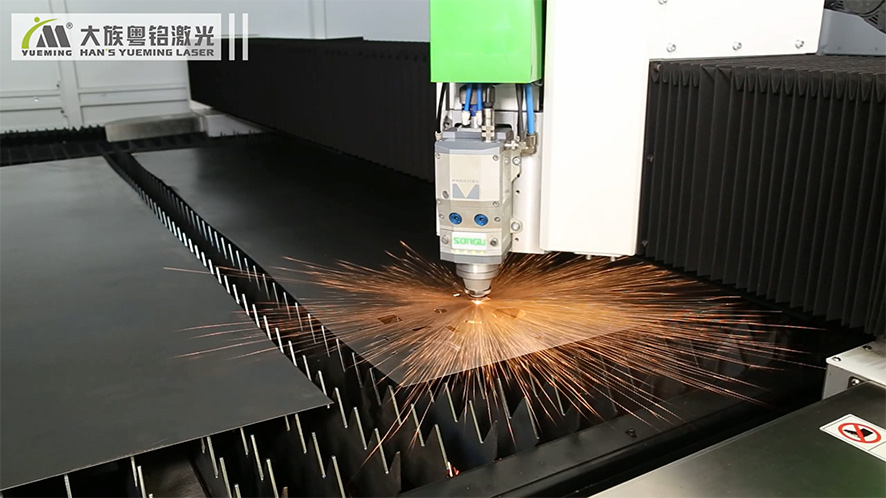

Sheet metal cutting is the most commonly used in sheet metal processing. Consider that in our life, there are thin sheets everywhere, such as computer cases, cabinets, TV cabinets, refrigerators, washing machines, etc. Different products involve thin plates of different shapes. In the past, thin plates were difficult to be processed quickly, as die stamping was needed during processing, the complexity can be imagined. However, the quotation and advantages of a 1000W laser cutting machine are given to you.

The quotation of a 1000W laser cutting machine is very transparent, which is from hundreds of thousands to hundreds of thousands RMB. The prices and configurations of major manufacturers are transparent, so buyers only need to compare and choose what they want to cooperate. Of course, it is important to not choose a company that has no after-sales guarantee while only take price into account. Since after-sales service is an important factor, after purchasing a 1000W laser cutting machine equipment.

Besides the factors of the price of a 1000W laser cutting machine, let's talk about the advantages of that. The fiber laser cutting machine is unique for cutting sheet metal, which is a technological revolution and the "processing center" in sheet metal processing. The advantages of fiber laser cutting machines are with a high degree of flexibility, fast cutting speed, high production efficiency, and short product production cycle. Also, the laser cutting machines are no cutting force, no deformation, no tool wear, and good material adaptability. Additional, no matter simple or complex shapes, the shape can be cut and formed at one time by laser cutting machines because of its narrow slits, good cutting quality, high degree of automation, simple operation, low intensity. That is why the automatic layout and nesting of cutting can be realized, material utilization rate is improved, production cost is low, and economic benefits are good.

The functions of mold stamping are almost the same as that of 1000W laser cutting machines, and the price of 1000W laser cutting machine is cheaper than that of mold stamping. It is quite expensive to open a set of molds, but the degree of flexibility is not high, and the function is unitary.

For cutting thin metal plates, the 1000W laser cutting machine presents the advantage in flexibility. As long as there is a picture, it almost can be achieved by the 1000W laser cutting machine.

PREVIOUS: Hundreds of creative front desk designs can be achieved by a fiber laser cutting machine

NEXT: Fiber laser cutting machine processes computer case: solidity is also an aesthetic

As a well-known 700w fiber laser cutting machine manufacturer, Han’s Yueming Laser produces laser cu...

Meet New High level Fiber Cutting machine...High level fiber cutting machine is the same as other laser equipment which has already recognized a...

How Much Does a 200W Laser Cutting Machine Cost?...Laser cutting machines for the cutting of non-metal materials are generally equipped with C02 laser...