ym@ymlaser.com

0086-18826950666

- Home

- About Us

- Products

- Application

- Service

- News

- Contact Us

By : Han's Yueming Laser Group Share: Back to list

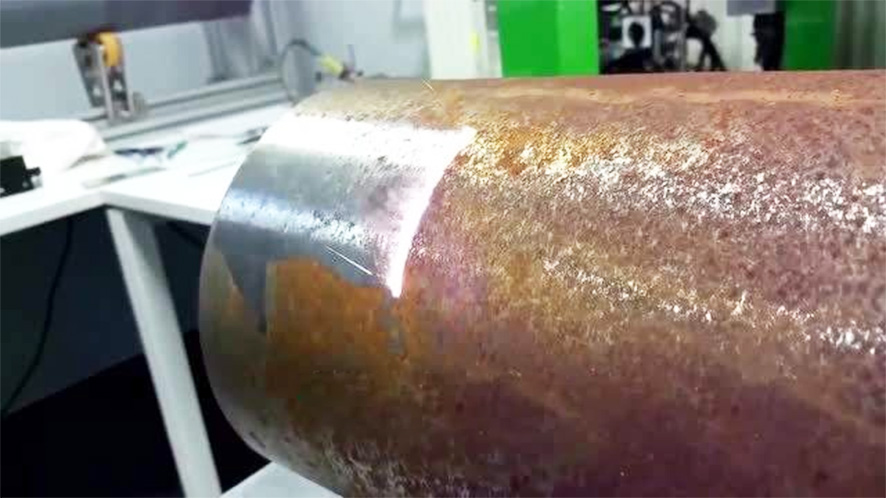

Rust is the inevitable existence of some metal products. In order to make the product beautiful and continue to use, it has to be derusted. The laser cleaning machine was born for this purpose. The laser cleaning machine has a remarkable effect in removing rust and can effectively remove rust. What are its advantages?

Laser cleaning machine

1. The laser cleaning machine is non-contact rust removal. It can be transmitted by optical fiber and combined with robots or manipulators to easily achieve remote operation. It can clean parts that are not easy to reach by traditional methods. It is cleaning ships, aircrafts, weapons, etc, Excellent choice for maintenance.

2. In addition to rust removal, the laser cleaning machine can also clean up different types of pollutants on the surface of various materials to achieve a high degree of cleanliness. It is a new application of surface engineering treatment. Pulsed laser is more suitable for titanium alloy surface cleaning and descaling, stainless steel weld bead cleaning, stainless steel welding spot cleaning, surface cleaning before and after welding of precision parts, and flange cleaning; ultraviolet laser is suitable for cleaning large components.

3. The laser cleaning machine is set through threshold calculation parameters, no contact, no grinding, no thermal effect, no damage to the substrate and human body, easy to operate, especially suitable for cleaning molds and cultural relics.

4. The laser cleaning machine does not require chemical solutions for rust removal, and there is no environmental pollution caused by chemical cleaning. It is a new technology, new process and new method to replace pickling and phosphating.

5. After the laser cleaning machine rust-removed and cleaned, the waste material forms a solid powder, which is small and easy to handle, does not cause re-pollution to the environment, and is green and environmentally friendly, which is the reform and development trend of industrial cleaning.

6. Traditional cleaning processes such as pickling and sandblasting inevitably cause visible damage to the surface of the substrate, so they are not suitable for cleaning thin plate materials below 30mm, and laser cleaning machines can show their talents.

7. The laser cleaning machine has strong flexibility and controllability. Through different parameter settings, the same laser cleaning machine can make the surface rough and improve the adhesion; preset effects can be set with different laser power, frequency, aperture, focal length, etc. , Do not exceed the limit as little as possible, only clean the required range and intensity, improve efficiency and reduce costs.

8. The laser cleaning machine can effectively clean up micron-level pollution particles, realize controllable fine cleaning, and is suitable for cleaning precision instruments and precision parts.

9. The rust removal of the laser cleaning machine can be used stably for a long time, without consumables and materials, only a small amount of electricity, low maintenance and operating costs, can be easily automated operation, and put into endless cycle use at one time.

10. The laser cleaning machine belongs to physical dry cleaning, replacing the waste of water resources caused by traditional industrial cleaning, replacing the cleaning fluid and builder required for traditional surface treatment, eliminating ODS ozone depleting substances, low carbon water saving and energy saving.

Today, when environmental protection laws and regulations are becoming stricter and people’s awareness of environmental protection and safety is increasing, laser cleaning machine rust removal can reduce the use of chemical agents and mechanical methods for cleaning. Its high-efficiency, environmentally friendly, and clean characteristics will become more and more important being widely used.

PREVIOUS: Sheet metal laser cutting machine restores the creative staircase design, each style is amazing!

As a well-known 700w fiber laser cutting machine manufacturer, Han’s Yueming Laser produces laser cu...

Meet New High level Fiber Cutting machine...High level fiber cutting machine is the same as other laser equipment which has already recognized a...

How Much Does a 200W Laser Cutting Machine Cost?...Laser cutting machines for the cutting of non-metal materials are generally equipped with C02 laser...