ym@ymlaser.com

0086-18826950666

- Home

- About Us

- Products

- Application

- Service

- News

- Contact Us

By : Han's Yueming Laser Group Share: Back to list

Environmentally friendly and healthy low-carbon bicycle travel is quickly becoming the vane of a new generation of fashion life.

The cool weather in early autumn is a good season for cycling.

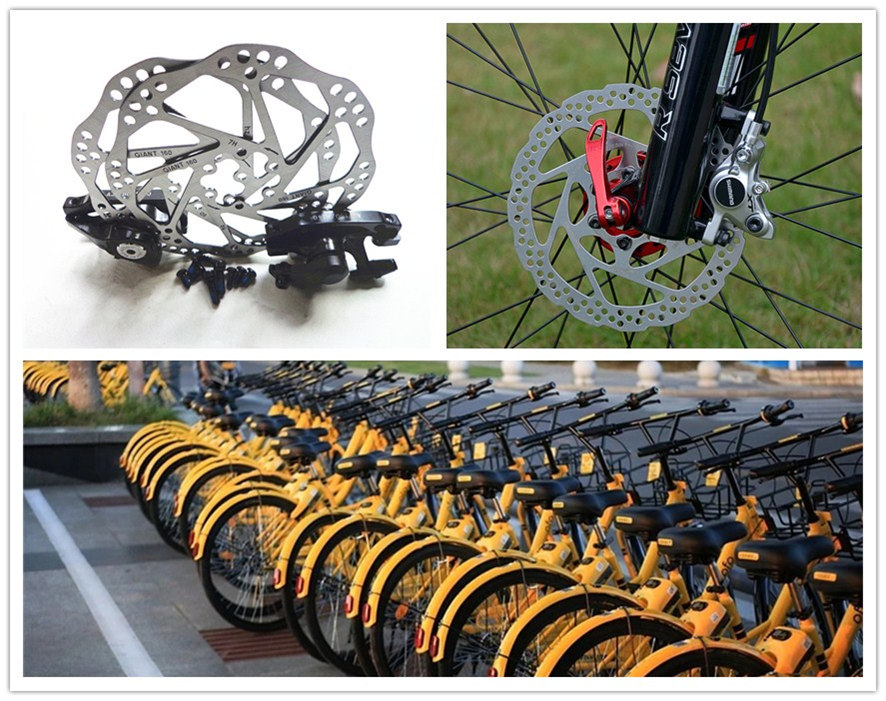

Brake pads are important components in bicycles.

The quality of the brake pads is related to the safety of the rider.

Most brake discs on the market are made of different types of metal materials.

The support of laser technology is naturally indispensable in the processing of thin metals.

The brake disc laser cutting machine cuts the brake discs, making green travel safer and more reliable.

The processing materials of the brake disc laser cutting machine are not limited.

Using a high-energy laser beam to focus on the surface of the metal plate,

Melt and vaporize the area irradiated by the ultra-fine focus spot on the metal,

Automatic cutting is realized by moving the spot irradiation position through the numerical control mechanical system.

The edges are round and smooth, so you don’t have to worry about scratching during installation and maintenance.

High-precision cutting ensures the perfect fit of each part.

Holes cut out by the brake disc laser cutting machine can help dissipate heat.

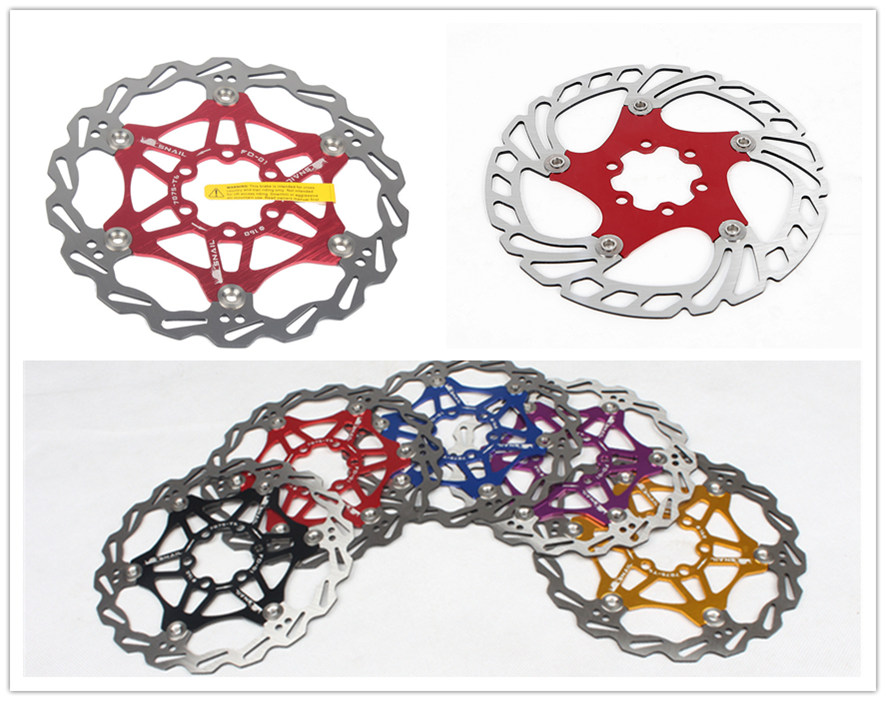

Variety is the spice of life,

It is especially obvious on custom bikes.

Many cycling enthusiasts like to modify their own cars,

According to your riding style and preferences,

To customize different styles of disc brakes,

Let the little-known brake discs change,

Become a unique business card for bicycles,

Increase the user's riding pleasure.

The brake disc laser cutting machine brings a cool appearance to the bicycle,

And brake discs that can adapt to multiple environments and road conditions,

Provide assistance for our safer and more efficient riding.

Whether it’s a leisurely ride aimlessly,

Or a long-distance wanton gallop,

Let's go green together!

Make a contribution to the clear water, blue sky and fresh air!

Recommended equipment

Gantry rack dual-drive fiber laser cutting machine

1. Features

◆Gantry rack double-drive structure, reinforced welded bed, large-scale gantry precision milling, tempering treatment and vibration aging to eliminate stress, ensuring that the deformation tolerance of the machine tool is within ±0.02mm;

◆The beam is manufactured by drawing process and finishing process, with light weight, high rigidity and good dynamic performance;

◆The cutting head adopts the leapfrog function, and the parabolic motion is used between the cutting contours. The contour switching process automatically realizes the "leapfrog", greatly improving the cutting efficiency;

◆With automatic centralized lubrication function, the traditional parts are automatically lubricated through system control without manual intervention, thereby ensuring the accuracy and service life of the transmission parts;

2. Process application

The brake disc laser cutting machine is mainly used for the rapid cutting of carbon steel, stainless steel, aluminum alloy, brass, galvanized sheet, aluminized zinc sheet, copper and other metal materials.

PREVIOUS: How much is a laser cleaning machine and what is the wholesale price?

NEXT: Sheet metal laser cutting machine restores the creative staircase design, each style is amazing!

As a well-known 700w fiber laser cutting machine manufacturer, Han’s Yueming Laser produces laser cu...

Meet New High level Fiber Cutting machine...High level fiber cutting machine is the same as other laser equipment which has already recognized a...

How Much Does a 200W Laser Cutting Machine Cost?...Laser cutting machines for the cutting of non-metal materials are generally equipped with C02 laser...