ym@ymlaser.com

0086-18826950666

- Home

- About Us

- Products

- Application

- Service

- News

- Contact Us

By : Han's Yueming Laser Group Share: Back to list

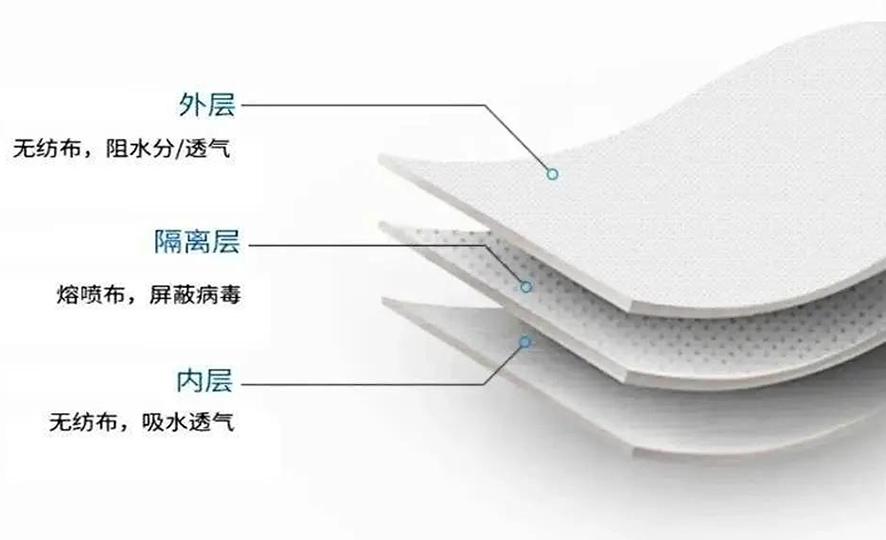

Although the output of masks has doubled after domestic enterprises resumed production, the raw material melt-blown cloth used to produce masks has become a key factor restricting the growth of mask production capacity. The mask is mainly composed of three layers: the outer waterproof non-woven fabric, the middle melt-blown filter layer, and the inner gauze or non-woven fabric.

(Three-layer structure of the mask)

In the three-layer structure, the production and processing of the outer layer and the inner layer are relatively simple, the most difficult and most important is the middle filter layer, which plays the most important role in shielding the virus. The material is made of ultrafine fiber with unique capillary structure, which has good filtering and shielding functions.

(Microstructure of melt-blown cloth after several times magnification )

Production process of melt-blown cloth

The core components for manufacturing these "unique capillary ultrafine fibers" are the most indispensable in the production process of masks and melt-blown non-woven fabrics-melt-blown non-woven fabric die. Its working principle is: using high melt index polymer slices, after extrusion heating, melting into a high-temperature melt with good flow performance, using high-temperature, high-speed hot air flow will be melted from the spinneret The fine flow blows into very fine fibers, making them extend in a fibrous shape, and then gathers into a fiber web on the receiving device, and uses their own residual heat to bond to each other to obtain a roll of melt-blown cloth.

The melt-blown cloth is ejected from many fine nozzles arranged on the spinneret, and the nozzle diameter is only 0.15 mm. It is also the core technology of the entire melt-blown nonwoven fabric die. This nozzle not only has a small size, but also needs to process a complex hole pattern on such a small nozzle Pieces.

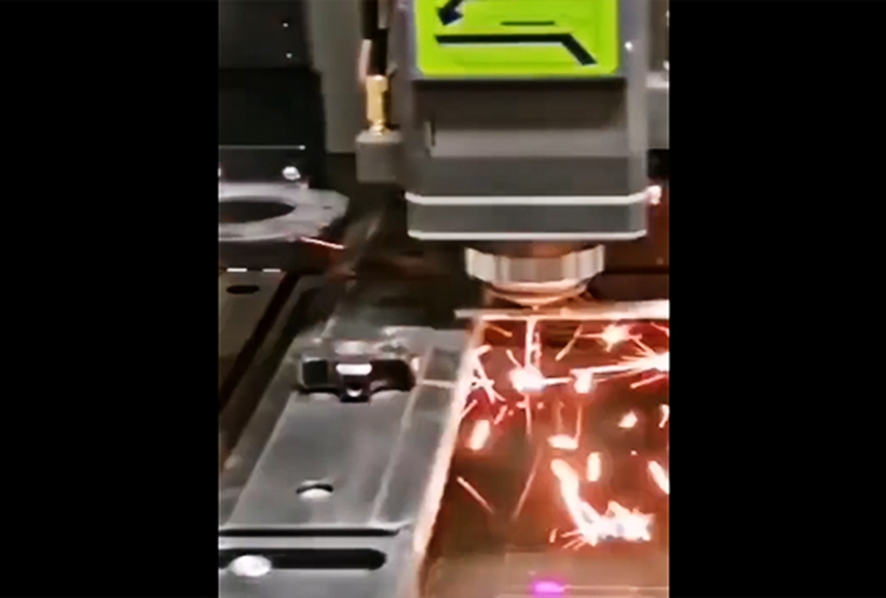

Laser punching ultra-fine nozzle

Traditional mechanical punching is costly. When drilling micro holes with a diameter of less than 0.2mm, a high-speed spindle with a spindle speed of more than 20,000 rpm is required, and the runout accuracy of the spindle and chuck must reach the micron level. As we all know, imported mechanical electric drills have high costs and large losses, regardless of the maintenance cost of the equipment or the loss rate, it is a large expenditure. At the same time, due to the low yield and high cost of the traditional mechanical electric drilling machine for drilling micro holes, it is increasingly not being adopted by enterprises. Replaced by ultra-fine laser perforated holes.

Laser punching is gradually gaining popularity in the industry. Laser punching has many advantages. Fiber laser heads can punch almost any metal sheet. The punching speed is dozens of times that of mechanical drilling machines. Smooth, can be drawn by computer to punch any shape. The advantages of punching 0.15mm nozzle holes on the spinneret are even more obvious. The laser can open 0.15mm fine holes in a 3mm thick die steel plate in seconds.

The skyrocketing price of mask machines and the surge in production also led to a surge in meltblown cloth demand. At present, all melt-blown cloth production lines are all working at full capacity to work overtime, but with the spread of the epidemic in the world, and the domestic production capacity of medical melt-blown cloth is limited, the demand for melt-blown cloth is still very large. Laser punching technology plays an incomparable role in the processing of spinneret nozzles, helping melt-blown cloth processing equipment to be launched quickly to meet the market's strong demand for melt-blown cloth.

Recommended laser cutting machine equipment:

Precision fiber laser cutting machine (PCF0606L-A)

Applicable materials: mainly used for stainless steel, aluminum alloy, titanium alloy, galvanized sheet, brass, and other metal materials.

Features:

1. Adopt high-precision marble and heat-treated steel structure to ensure the long-term stability of the equipment;

2. The motion mechanism adopts linear motor, with fast response speed and high sensitivity, which can realize high-speed high-speed movement with short stroke and high dynamic performance;

3. With high resolution, it can achieve higher positioning accuracy;

4. It has the following functions of power, frequency and speed to improve the cutting effect.

As a well-known 700w fiber laser cutting machine manufacturer, Han’s Yueming Laser produces laser cu...

Meet New High level Fiber Cutting machine...High level fiber cutting machine is the same as other laser equipment which has already recognized a...

How Much Does a 200W Laser Cutting Machine Cost?...Laser cutting machines for the cutting of non-metal materials are generally equipped with C02 laser...