ec@ymlaser.com

+86 139 2589 8201

- Home

- About Us

- Products

- Application

- Service

- News

- Contact Us

- Web

By : Han's Yueming Laser Group 2017-1-18 Share: Back to list

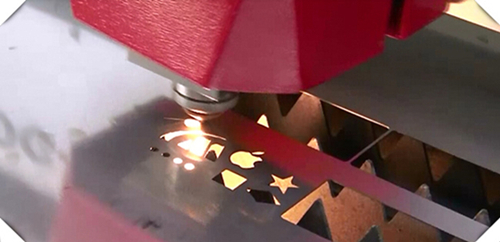

This paper will analyze how to get efficient solution of alloy cutting issues with own experiences rather than empty talk. Metal is a relatively difficult to cut material because of its large hardness , it is prone to get error when cutting, and it is difficult to ensure cutting accuracy, so here we should base on ways and means of laser cutting machining to select metal laser cutting machine, so how to process sheet metal ? Technical engineer will provide a detailed analysis. Compared with the general steel, alloy cutting difficulties mainly in the following four areas:

A. The main ingredients of nickel-base alloy of nickel and chromium, with further addition of small amounts of other elements: molybdenum, tantalum, niobium, tungsten, etc., it is worth noting that, tantalum, niobium, tungsten carbide is used to manufacture (or high-speed steel), the main component of oxidized tip tap, tip tap processing these oxide high-temperature alloys will produce diffusion wear and abrasive wear.

B. cutting power. Compared with steel materials, the strength of Superalloy turbine is often higher, about 30%. At more than 600 ℃ cutting temperature, strength of the Ni-base superalloy materials still higher than ordinary steel materials. Not enhanced processing unit superalloy cutting force in 4000N / mm2 or more, while the ordinary steel only 2500N / mm2.

C. hardening tendency of large. For example GH4169 unreinforced matrix hardness treatment about HRC37, the surface after metal laser cutting machine will produce about 0.03mm hardened layer hardness to around HRC47, hardening up to 27%. Hardening phenomenon has a great influence on the oxidation tip tap life, often have serious boundary wear.

D. poor thermal conductivity material. A lot of cutting heat generated by the oxidation of the alloy to withstand the cutting tip tap, tip withstand up to 800 ~ 1000 ℃ cutting temperature, high temperature and high cutting forces, will lead to plastic deformation of the cutting edge, adhesion and diffusion wear.

PREVIOUS: The fashion collision between cotton cheongsam and laser technology

NEXT: Fiber laser marking machine can successfully save the market?

As a well-known 700w fiber laser cutting machine manufacturer, Han’s Yueming Laser produces laser cu...

Meet New High level Fiber Cutting machine...High level fiber cutting machine is the same as other laser equipment which has already recognized a...

How Much Does a 200W Laser Cutting Machine Cost?...Laser cutting machines for the cutting of non-metal materials are generally equipped with C02 laser...